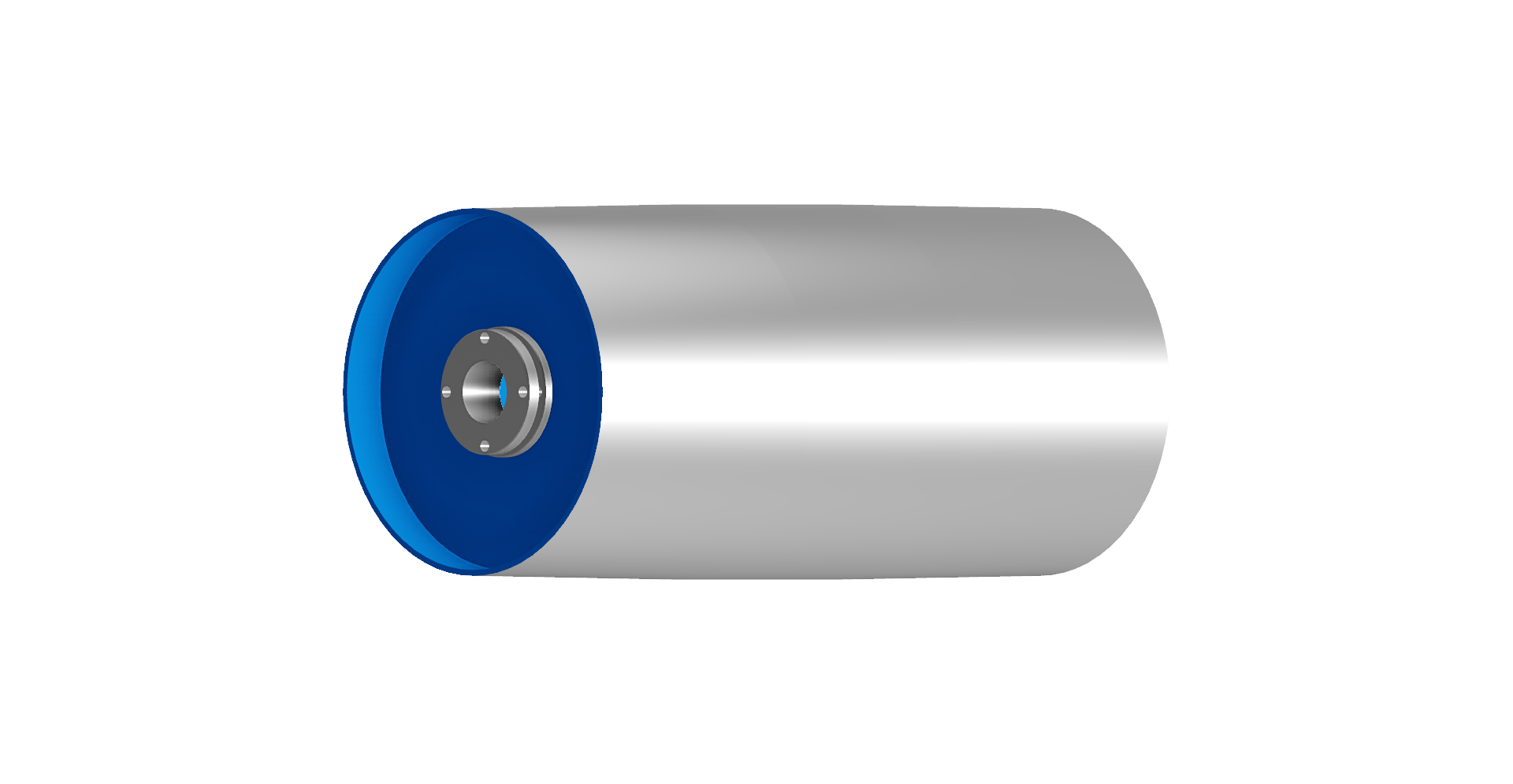

Luff manufactures drum pulleys fabricated from heavy schedule pipe allowing for improved performance and longer life, versus the competitors rolled steel shell. The strength of these pulleys means less maintenance and reduced belt wear. Luff typically machines a large trapezoidal crown angle, providing superior belt tracking and ensuring maximum pulley concentricity. Having maximum contact with the belt aids in belt tracking, reduces vibration and stress on bearings and lowers decibels during operation.

There are a variety of lagging options available for Luff drum pulleys to protect your investment even further.

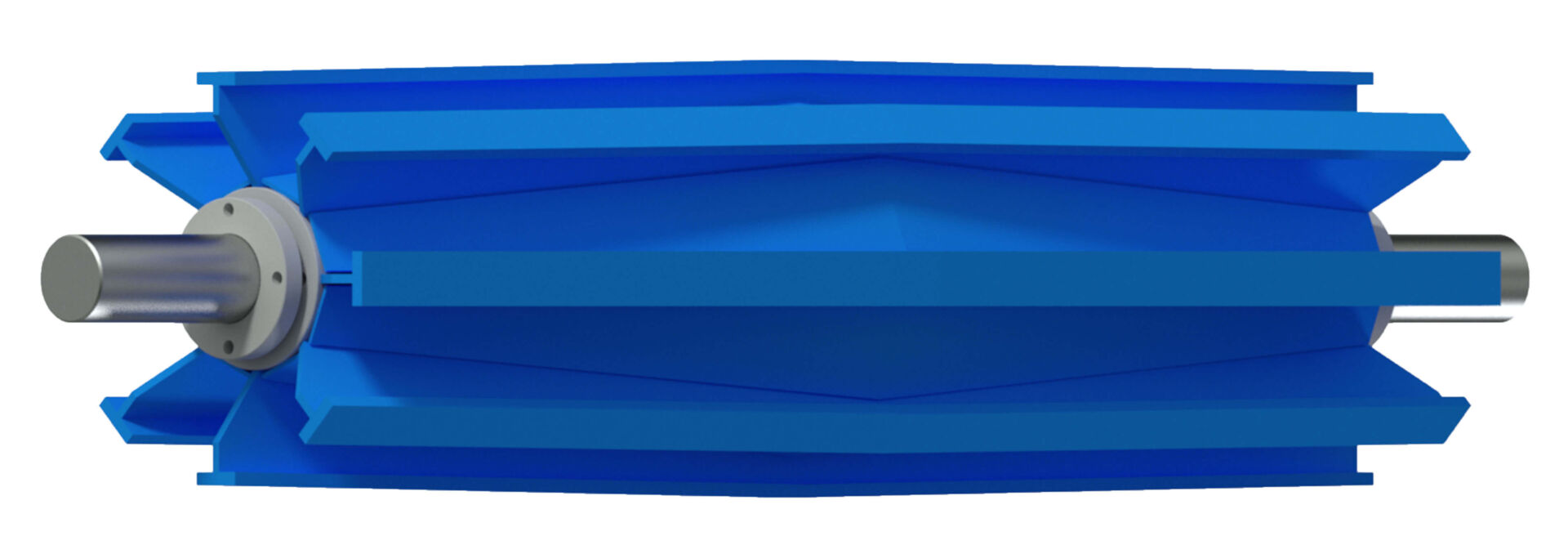

Luff Wing Pulleys are primarily used on light and medium duty conveyor systems. Wing pulleys break the surface contact with the belt creating a vibration that cleans off sticking material. The material is than discharged by the deflectors to the sides of the conveyor.