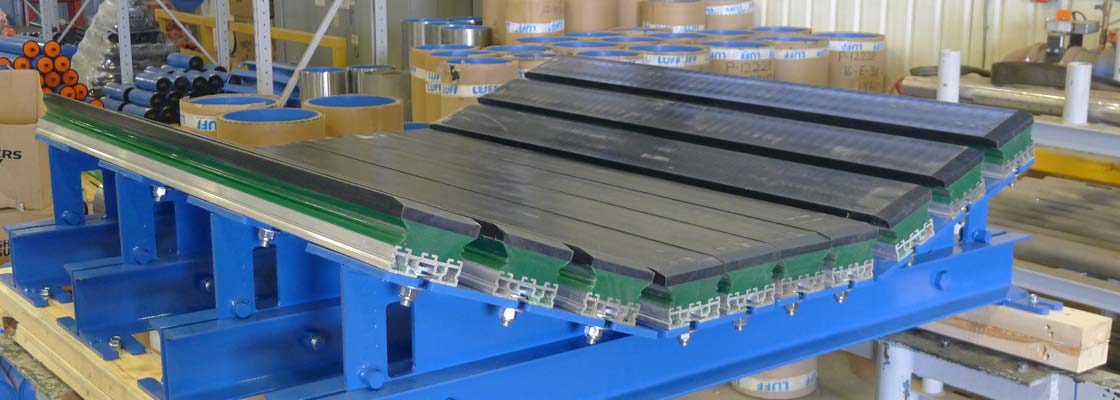

A conveyor impact bed is a piece of machinery utilized to support conveyor systems and belts. The structure is used to cushion the impact of plummeting material. Typically installed at the bottom of a chute, these beds are produced with shock receptors that absorb the contact of heavy materials falling from above.

Conveyor impact beds are used in a wide range of industries, including aggregate, cement, metal, non-metal, mining, and more. Here is an explanation of the role of conveyor impact beds and are five things you need to know about them.

The Role of Conveyor Impact Beds

Impact beds are built to absorb shock and support the conveyor belt at transfer points, reducing wear and maintenance costs. They are particularly crucial for conveyors moving bulk and jagged materials in industries such as mining and quarrying.

The impact bed is made of several impact bars, each comprising a high molecular polyethylene surface, an aluminum alloy frame, a high-quality natural rubber damping layer, and a metal seat. These components work together to cushion the collision and minimize damage to the belt.

5 Things to Know About Conveyor Impact Beds

1. The Benefits of Impact Beds Are Invaluable

The most significant advantage of conveyor impact beds is the cost-saving factor for companies. Minimizing the need to replace parts reduces downtime and maintenance costs, and operations are enhanced, positively impacting a company’s bottom line.

Along with the cost-saving factor, impact beds:

- Prevents Belt Damage and Extends Lifespan: The surface contact between the impact bar and the conveyor belt helps prevent puncture damage and reduces belt sagging at heavy loading points. The smooth surface of the impact bed minimizes friction, ensuring smooth operation of the conveyor belt and prolonging its service life. Maintaining the integrity of your belt is critical to your operations.

- Reduces Maintenance Costs: By evenly distributing the stress on the belt, impact beds help eliminate material splashing and leakage, significantly lowering daily repair and maintenance costs.

- Safety Impact: Impact beds are crucial for industrial safety. They absorb shock and reduce vibrations from heavy machinery, protecting workers and products alike. Impact beds also help preserve the structural integrity of surrounding areas by cushioning against vibrations that can cause damage over time. They reduce noise pollution, creating a more comfortable working environment for employees.

- Noise Reduction and Heat Protection: Impact beds act as shock absorbers, dampening sound and vibrations from heavy machinery, thus reducing noise levels and improving safety standards. They also provide heat protection by decreasing friction, preventing excess wear on machinery and maintaining optimal efficiency for longer periods.

- Maintenance Reduction and Cost Savings: Impact beds reduce the need for regular maintenance and repairs, saving businesses time and money. They provide reliable protection against heavy materials, preventing costly repairs and ensuring peak performance with minimal downtime. Additionally, impact beds help increase efficiency, reduce energy costs, and improve overall performance.

2. How an Impact Bed Works

Impact beds are designed to absorb the force of material falling at transfer points along a conveyor system. They consist of multiple impact bars, each made up of four main components: a durable aluminum alloy frame, a high-quality rubber dampening layer, a solid metal seat, and a polyethylene surface.

The core function of the impact bar is to cushion the impact, reducing damage to the conveyor belt. This added protection helps extend the lifespan of the belt and ensures smoother operation. Carefully engineered and constructed, impact beds reduce the risk of tearing or wear, helping companies save on costly maintenance and repairs over time.

3. The Types of Impact Beds Available

Impact beds are commonly categorized by type and application. The two main classifications are ordinary and flame-retardant. Ordinary impact beds are typically used in facilities such as cement plants, mines, and docks, while flame-retardant models are ideal for coal plants due to their enhanced safety features.

Various structural designs are available, including spring, flat, parallel, and heavy-duty composite impact beds. Two popular design types are I-beam steel and channel steel constructions. Channel steel is often used in power plants, whereas I-beam steel designs are more common in mines and cement facilities.

The cost of an impact bed depends on the working environment and the specific design requirements. If you’re unsure which type is right for your application, Luff Industries offers a wide range of reliable, high-performance impact beds to meet the needs of virtually any project.

4. The Proper Method to Choose an Impact Bed

Choosing the correct impact bed requires three key pieces of information: the belt width, the intended application, and the shape or mold of the conveyor belt. These variables help manufacturers recommend the most suitable impact bed for your specific needs.

5. Installment Guide of Impact Beds

Luff Industries delivers impact beds pre-assembled, with the exception of the adjustable rod. To install the bed properly, follow these steps:

- Lift the impact bed onto the center frame above the conveyor belt, aligning it beneath the material drop zone. Secure the bed to the frame using the corner bolts on both sides of the base.

- Install the adjustable rod to configure the side structure to match the groove angle of the conveyor system. This angle is adjusted by aligning the holes on the side frame with the rod.

Make sure there are rollers installed at each end of the bed to avoid premature wear and ensure smooth operation. Having the appropriate tools on hand—such as lifting equipment and standard construction tools—will help streamline the installation process and ensure a secure fit.

Industry-Specific Support by Luff Industries

Luff Industries offers a range of conveyor components, including high-quality impact beds tailored to various industries. Whether in construction, oil and gas, or managing a small- to medium-sized enterprise, Luff Industries has the expertise to provide the right impact bed for your needs. Our impact beds are designed to CEMA standards, ensuring they are built to absorb shock, minimize belt damage, and reduce maintenance costs, ensuring your operations run smoothly and efficiently.

Being aware of the role of conveyor impact beds and investing in high-quality components can significantly enhance the longevity and efficiency of your conveyor belt systems. Don’t let material handling challenges slow you down. Explore our impact bed solutions and find the perfect fit for your conveyor system. Contact us today to help you maintain consistent, reliable operation and protect your investment.