Conveyor systems are integral to numerous industries, including mining, manufacturing, and logistics, where the efficient and reliable movement of materials is critical. At the heart of these systems are the idlers.

Standard idlers may not be ideal for your operations, causing issues with your conveyor performance. Custom idlers play a vital role in optimizing your overall operations. Conveyor idler manufacturers specifically design them to meet the unique requirements of each conveyor system and offer several benefits that enhance efficiency and reduce operational costs.

Optimized Performance

Custom idlers are tailored to the specific needs of a conveyor system, considering factors such as load capacity, belt speed, and environmental conditions. This optimization ensures that the idlers provide the best possible support for the conveyor belt, reducing sagging and maintaining proper belt alignment. The result is a smoother operation with less friction and wear, improving conveyor performance and efficiency.

Enhanced Durability

While effective, standard idlers may not always be suited to the harsh conditions encountered in various industrial applications. On the other hand, custom idlers are designed with specific materials and engineering solutions that enhance their durability.

For example, high-quality bearings and specialized coatings can protect idlers from abrasive materials, extreme temperatures, and chemical exposure. This increased durability reduces the frequency of replacements and maintenance, decreasing downtime and associated costs.

Energy Efficiency

Properly functioning idlers are crucial for maintaining a conveyor system’s energy efficiency. Custom idlers are designed to minimize friction between the conveyor belt and the idlers themselves, reducing the power required to move materials. This lowers energy consumption and decreases the strain on the conveyor motor, extending its lifespan and reducing operational costs.

Reduced Maintenance

One significant advantage of custom idlers is their contribution to reducing maintenance requirements. By addressing specific operational challenges and environmental conditions, custom idlers are less prone to wear and damage. This reliability means fewer breakdowns and less frequent maintenance, allowing for uninterrupted operation and significant cost savings over time.

Improved Material Handling

Custom idlers are designed to enhance material handling efficiency by providing consistent support and alignment for the conveyor belt. This consistency helps prevent material spillage, jams, and uneven loading, which can cause disruptions in the conveyor system. With custom idlers, materials move smoothly and efficiently, improving the overall throughput and productivity of the operation.

Extended Conveyor Belt Life

The conveyor belt is often the most expensive component of a conveyor system. Custom idlers help extend the life of the conveyor belt by reducing friction and ensuring even load distribution. This minimizes wear and tear on the belt, delaying the need for costly replacements and reducing the total cost of ownership for the conveyor system.

Application-Specific Solutions

Every industrial application has unique requirements and challenges. Custom idlers can be designed to meet these specific needs, whether it involves handling heavy loads, operating in corrosive environments, or managing high-speed conveyor belts. This customization ensures that the idlers provide the best performance for the specific application, leading to more efficient and reliable operations.

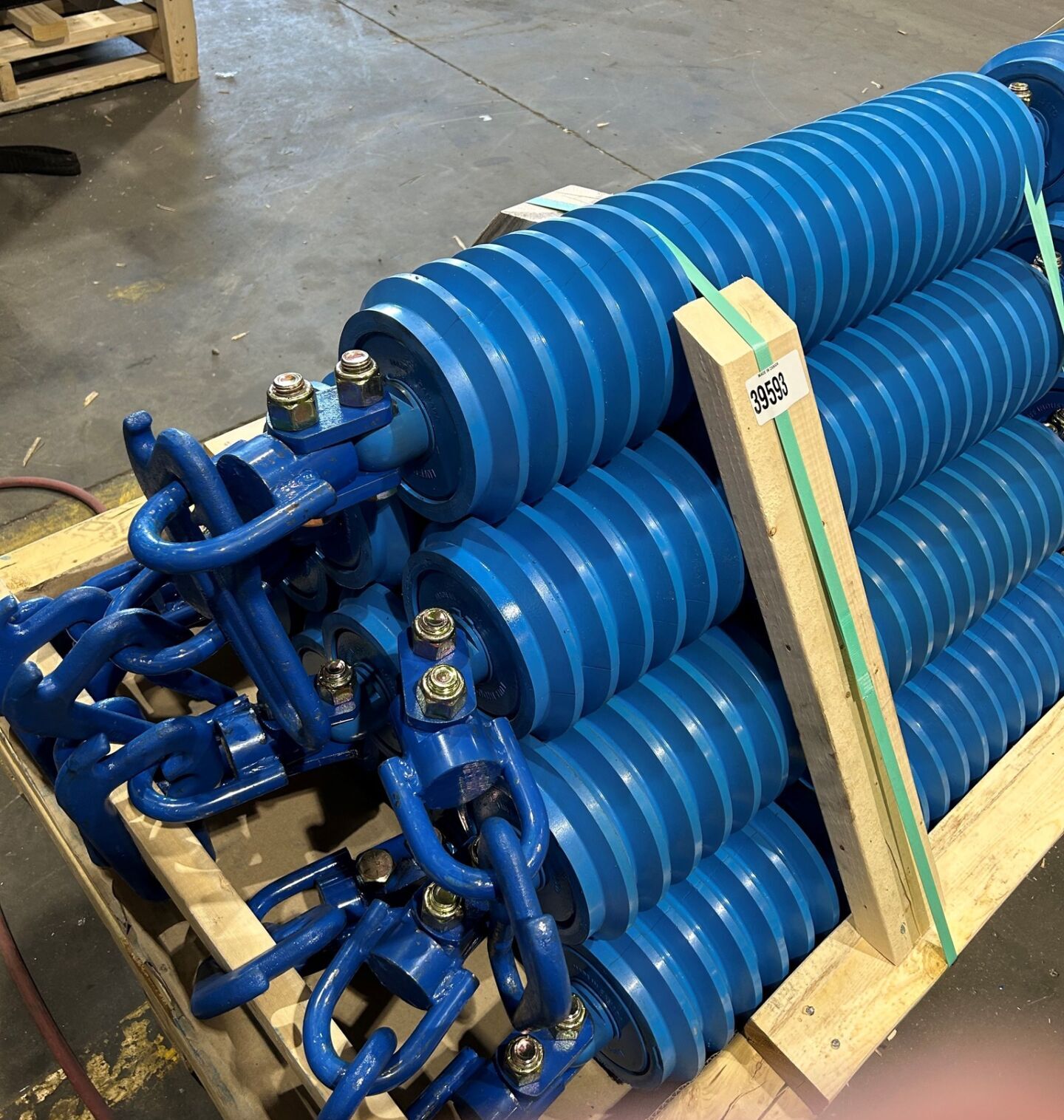

Custom Idlers from Luff Industries

Custom idlers are an essential component for maximizing conveyor efficiency. Their tailored design and construction provide optimized performance, enhanced durability, energy efficiency, reduced maintenance, improved material handling, extended conveyor belt life, and application-specific solutions.

Investing in custom idlers from one of the top conveyor idler manufacturers, like Luff Industries, ensures your conveyor system operates at peak efficiency, ultimately leading to better production and lower costs. Our custom idlers and conveyor components are designed and undergo rigorous testing to meet the highest standards, ensuring reliability and performance in the most demanding applications.