Wing pulleys are an ideal alternative to conventional drum pulleys for environments that experience excessive material build-up. Helix Wing Pulleys provide a unique design that allows for constant belt contact with open voids to expel and dislodge material. This leads to better traction, reduced abrasion on the belt and pulley, and a quieter operation.

Let’s take a closer look at the role of Helix Wing Pulleys on the conveyor system and its advantages.

How does a Helix Wing Pulley work?

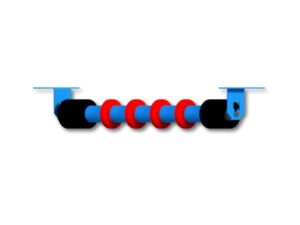

Wing pulleys are used on light and medium-duty conveyor operations and can typically be found on the tail end of bulk handling systems. The Helix Wing Pulley is a robust pulley construction that maintains constant belt contact at a helix angle. This intelligent design works for conveyor systems that have a tendency for the loose material to reside on the underside of the conveyor belt.

What are the advantages of Helix Wing Pulleys?

- Less vibration – Vibration is reduced with a helix design that remains in constant belt contact. This means less stress on the belt and bearings, quieter operations, and less wear on the belt. Helix Wing Pulleys effectively increase the life of conveyor systems by minimizing the need for maintenance and replacement parts.

- Rejects material – Deflectors discharge material out of harm’s ways and pulls it to the sides of the conveyor where it falls away from the pulley and belt contact surface.

- “Self-cleaning” belt – Traditional drum pulleys feature a design with intermittent belt contact, which entraps and recirculates the material rather than displacing it. Excessive material build-up often leads to belt damage and pulley failure. With a helix angle, the material can be shed away from the belt surface without breaking contact to reduce build-up effectively.

Key takeaways

The right pulley design for specific applications is essential for productivity and maintaining a good workflow. While simple in design, the helix can be the difference between unnecessary expenses from premature wear on the belt and an improved bottom line from cost-savings and a more efficient conveyor system. Using the correct pulley protects your investment by enhancing your system and increasing pulley life.