In industrial environments, maintaining the efficiency and longevity of conveyor systems is crucial for smooth operations. The conveyor belt brush cleaner is one essential tool for ensuring clean, safe, and effective conveyor operation.

Designed to minimize material carryback and protect conveyor components, these cleaners are a versatile and cost-effective solution for industrial applications. Let’s explore the key benefits of incorporating belt brush cleaners into your conveyor system.

Enhanced Conveyor Efficiency

Material build-up on conveyor belts can cause inefficiencies, leading to decreased productivity and potential system malfunctions. Belt brush cleaners actively remove excess material from the belt surface, ensuring it remains debris-free. This minimizes material loss and ensures bulk materials move seamlessly through the system. For non-flat belts, such as cleated or grooved designs, brush cleaners offer unmatched cleaning capabilities by reaching into troughs and raised sections.

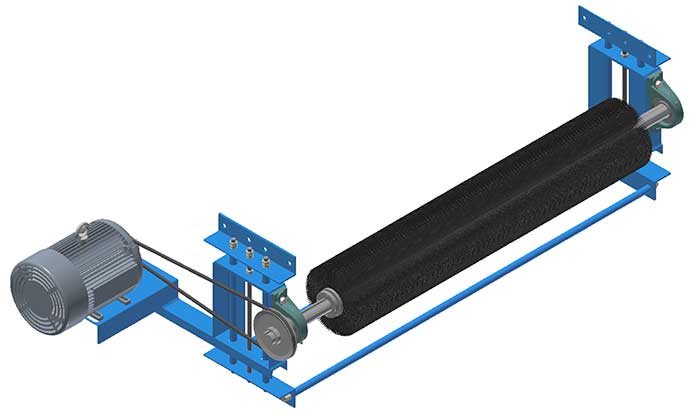

Compact and Easy to Install

Conveyor belt brush cleaners offer a practical solution in operations where space is limited. The brush’s compact design allows them to be installed near the head pulley on the return side of the belt. They can be used independently or with primary scrapers for enhanced cleaning performance. Their simple installation and adjustability make them a low-maintenance addition to your conveyor system.

Prolonged Belt Life

Material that adheres to the belt surface often accumulates on pulleys, idlers, and other conveyor components, accelerating wear and tear. By effectively removing carryback, belt brush cleaners protect these components, reducing the risk of abrasion, misalignment, and fraying. This leads to a longer lifespan for both the belt and other critical parts of the whole system, reducing the need for frequent replacements.

Versatility Across Applications

Belt brush cleaners suit various materials, including dry, wet, sticky, abrasive, or static-charged substances. They are particularly effective for fine particle materials like cement, fertilizer, mineral sands, and wood chips. Brush cleaners are also ideal for confined spaces where traditional scrapers or spray bars may be impractical.

Increased Safety

Excess material that falls beneath the conveyor system can create hazardous working conditions for employees. Carryback can lead to slippery floors, potential health risks from airborne dust, and even equipment malfunctions. By keeping belts clean, belt brush cleaners contribute to a safer working environment, reducing the risk of workplace accidents.

Reduced Maintenance Costs

Regular maintenance of conveyor systems can be time-consuming and expensive. Material carryback increases maintenance requirements by causing material accumulation on components and surrounding areas. Belt brush cleaners help prevent this by efficiently sweeping away debris before it becomes an issue, reducing cleanup efforts and minimizing downtime for maintenance.

Investing in Belt Brush Cleaner

Belt brush cleaners are an invaluable tool for maintaining industrial conveyor systems. Their ability to handle challenging materials, improve belt performance, and reduce maintenance costs makes them an excellent investment for operations aiming to maximize efficiency and safety. With customizable options such as bristle type, speed, and direction, these cleaners can be tailored to fit the unique demands of your industrial application.

Invest in a belt brush cleaner today and experience the benefits of a cleaner, more efficient conveyor system designed to handle the demands of industrial operations.

Conveyor Belt Brush Cleaners from Luff Industries

Enhance your conveyor system’s performance and longevity with Luff’s conveyor belt brush cleaner. Engineered to reduce belt wear, prevent build-up, and improve tracking, our brush cleaner is designed for optimal efficiency in any application.

With adjustable brush speed and customizable options for bristle material and size, Luff provides a tailored solution to keep your conveyor running smoothly. Backed by our industry-leading 24-month warranty, you can trust Luff for reliable, high-quality conveyor components that stand the test of time.