In heavy industries, maintaining the efficiency and longevity of your equipment is a necessity—especially for conveyor systems that handle demanding tasks like crusher feed. These systems operate in harsh environments and face constant stress from heavy, abrasive materials. To protect your conveyor system and to ensure its long-term performance, Industrial conveyor impact beds are essential. At Luff Industries, we understand the role these components play in absorbing impact and preserving the integrity of your conveyor system.

Understanding the Challenge

Crush feed belts are subject to intense pressure and impact from large, heavy materials. This constant pressure can lead to belt sag, misalignment, and accelerated wear and tear, all of which result in significant downtime and expensive repairs. The key to mitigating these issues is effective impact absorption and support, which are provided by conveyor impact beds.

How Do Impact & Slider Beds Work?

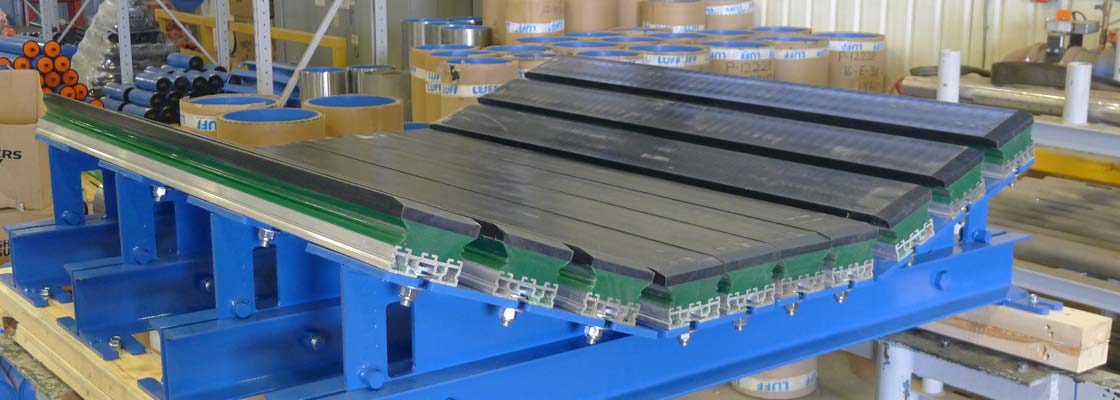

Conveyor impact beds and slider beds act as a support base for conveyor belts. They’re designed to prevent belt damage and belt sagging from heavy product loading points. For this reason, it’s best to install impact beds at conveyor feed and transfer points.

Impact beds are made from heavy-duty materials that are impact-resistant, ensuring they can operate reliably in heavy-duty environments. Custom and low-profile impact bed designs are available to fit all positions. Their unique frame design allows the impact bars to easily slide out in two sections for more efficient removal and placement, further reducing maintenance and downtime costs.

What to Look for in a Conveyor Impact Bed

When choosing a conveyor system, it’s important to consider the type of bed that best suits your needs. Here’s a quick comparison:

- Slider Bed Conveyors: These conveyors use a solid bed of low-friction material, making them ideal for heavy-duty applications, abrasive materials, and inclines/declines.

- Roller Bed Conveyors: These conveyors use rollers to move materials, making them suitable for lighter loads, fragile items, and accumulation.

The choice between a slider bed vs roller bed conveyor depends on the specific materials you’re handling and the requirements of your operation.

Regardless of the type of conveyor bed you choose for your system, there are several key features to look for. These include:

- Durability: The impact bed should be made from high-quality materials that can withstand heavy impacts and resist wear and tear.

- Energy Absorption: Effective energy absorption is crucial for minimizing the impact on the belt.

- Support: Proper support prevents belt sag and ensures smooth material flow.

- Adjustability: Adjustability allows the impact bed to adapt to different load sizes and conditions.

- Maintenance: Choose impact beds that are easy to maintain and have readily replaceable parts.

Benefits of Heavy-Duty Conveyor Impact Beds

Heavy-duty demands placed on crusher feed belts require robust solutions to ensure longevity and efficiency in challenging environments. Impact beds are critical in minimizing wear and tear, reducing downtime, and extending the life of your conveyor system. They offer a range of benefits, including:

- Impact Absorption: Effectively absorbs the force of falling materials.

- Belt Support: Provides full support to the belt in loading zones.

- Reduced Maintenance: Minimizes wear on impact idlers and frames, reducing maintenance needs and associated costs.

- Damage Prevention: Prevents premature wear and damage to the belt.

- Spill Control: Eliminates product spills and reduces dust accumulation.

If your conveyor system handles heavy, sharp, or unusually shaped materials, and you’re noticing wear on impact idlers and frames, incorporating impact beds can be a valuable solution to enhance the longevity and efficiency of your operation.

Invest in Your Conveyor System with Luff Industries

Luff Industries specializes in providing heavy duty conveyor impact beds designed to withstand the toughest conditions. Our impact beds offer:

- Robust Construction: Built with high-quality materials for maximum durability.

- Superior Energy Absorption: Engineered for optimal impact absorption, protecting your belt and other components.

- Optimal Support: Provides consistent support to the belt, preventing sag and ensuring smooth operation.

- Adjustability and Customization: We offer customizable solutions to meet your specific needs.

- Ease of Maintenance: Designed for easy maintenance and quick part replacement.

Investing in high-quality conveyor impact beds is an investment in the longevity and efficiency of your entire conveyor system. Luff Industries’ impact beds are designed to meet the demands of heavy-duty applications, providing reliable protection and ensuring smooth, efficient operation.

Contact Luff Industries today to learn more about our impact beds and how we can help optimize your conveyor system.