The Clean Weave Return Roller | How This Luff Industries Conveyor Component Is Improving Your Operations

Material carryback and debris buildup on the return side of a conveyor system are more than just...

Read moreHappy Holidays From Luff Industries!

From all of us here at Luff Industries, we wish you and your loved ones a Happy...

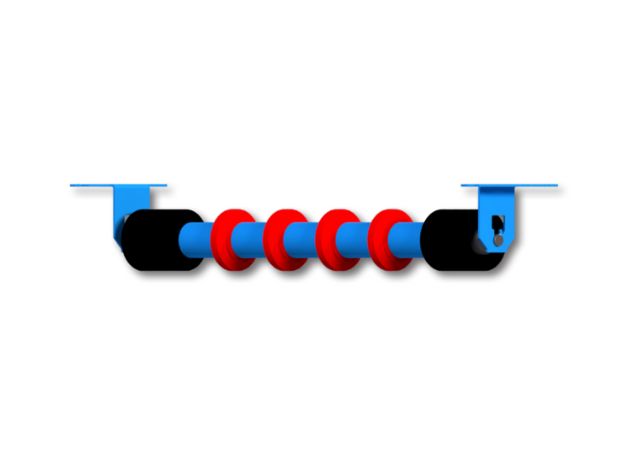

Read moreHow Luff Industries’ Urethane Disc Return Rollers | Extend Your Conveyor Belt Life by 5x

In demanding material handling environments, return-side wear is one of the most common – and costly –...

Read moreThe Urethane Beater Return Roller | Delivering Years of Leading Performance in Harsh Conditions

Keeping conveyors clean and efficient is absolutely critical when it comes to demanding industries like mining, sand...

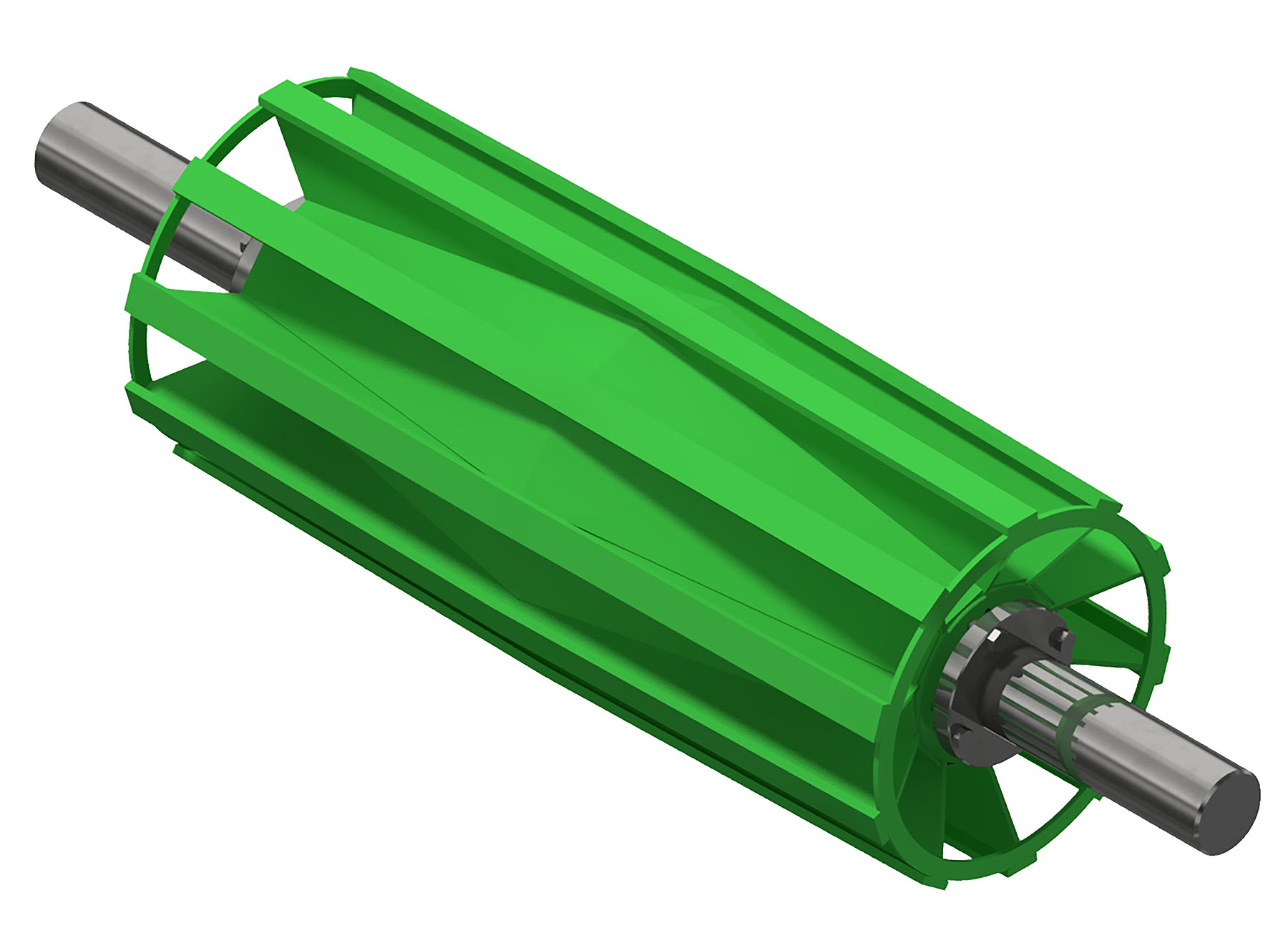

Read moreThe Wear Wolf Pulley Deep Dive | Why It Outlasts the Competition

When it comes to keeping your operation running efficiently, downtime isn’t just inconvenient – it can be...

Read moreWhy Every Plant Should Upgrade to Urethane Beater Return Rolls for Carry Back Control

In industries such as sand & gravel, aggregates, and mining, material carry back isn’t only a nuisance...

Read moreUnderstanding the CEMA Rating: A Comprehensive Guide by Luff Industries

In bulk material handling, efficiency and safety go hand in hand. Choosing the right conveyor equipment is...

Read more6 Simple Steps to Keep Your Industrial Conveyor System Running Smoothly

When your industrial conveyor system is the backbone of operations, even minor issues can cause costly downtime,...

Read moreThe Science Behind the Strength | What Makes Wear Wolf Material So Tough?

When it comes to industrial conveyor pulleys, downtime caused by premature wear is more than an inconvenience...

Read moreThe Most Common Conveyor System Issues and How to Prevent Them

Industrial conveyor systems are essential for efficient material handling across numerous industries. But like any machinery, they’re...

Read morePreventing Early Failure of Industrial Conveyor Systems

When operating complex industrial conveyor systems, proactive maintenance and a deep understanding of common failure points are...

Read moreCelebrate Canada Day with Luff Industries

As we gather to celebrate Canada Day, Luff Industries is proud to reflect on our journey as...

Read more