Mining operations depend on heavy industry conveyor systems to improve efficiency, safety and productivity. Conveyor systems transport extracted materials from mining sites to processing areas, allowing for efficient material flow and handling. Robust conveyor belt systems are engineered to endure the substantial impact of stone, ores, wood, and gravel. Essential to these systems is a sturdy structure and highly durable industrial belting capable of withstanding extreme conditions.

Heavy industry conveyor components are essential for mining operations, supporting material handling, transportation, and more.

Key Features and Capabilities of Heavy-Duty Conveyors

Heavy industry conveyor systems are built to withstand the harshest environments and are designed to tackle the challenges of tearing, abrasion, and wear. These conveyors have proven capabilities in effectively transporting various materials, including cement, coal, granite, gravel, recycled materials, iron ore, wood, paper, and pulp. Heavy-duty belt conveyors are up to the task, whether it’s a quarry, mine, steel mill, cement plant, power plant, or aggregate crushing facility.

Built for Mining: Key Features of Heavy-Duty Conveyor Systems

Heavy-duty conveyors in mining are designed to tackle harsh environments and rigorous material loads. Whether transporting raw materials from pit to plant or managing long-distance transfers across rugged terrain, these systems support operations at mines, quarries, aggregate sites, and more.

They offer advantages like:

- Efficient loading and unloading of trucks, railcars, or vessels

- Expanded stockpiling capacity through radial stackers

- Reduced reliance on trucks via overland conveyor configurations

- Consistent raw material handling, even in high-impact zones

- Improved site logistics through streamlined transport of materials

Behind this performance lies the integrity of the system’s components.

The Role of Idlers, Pulleys & Impact Beds in Mining Productivity

In the mining industry, conveyor components such as idlers, pulleys, impact beds, and accessories are crucial. These components are vital for the efficient and reliable operation of conveyor systems, which are the backbone of material handling processes in mining operations.

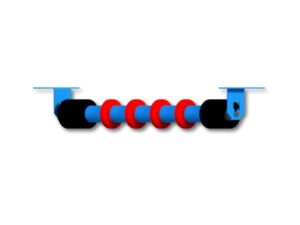

Idlers

Idlers support the conveyor belt and material load, providing a smooth surface for the belt to run on. They are crucial for maintaining the integrity of the conveyor belt and ensuring efficient material transport. Proper design significantly reduces the risk of contamination and extends the life of the idler, contributing to lower maintenance costs and increased uptime for mining operations.

Pulleys

Pulleys are pivotal in driving the conveyor belt and controlling its tension, ensuring it operates smoothly and efficiently. Pulleys should be designed to withstand the demands of the most challenging conveyor applications. A robust construction absorbs more stress, reduces shell deflection, and protects against abrasive wear, making them especially suited for the harsh environments found in mining.

Impact Beds

Impact beds protect the conveyor belt from damage at loading points, where the material drop can cause significant wear and tear. By absorbing the energy of falling materials, impact beds extend the lifespan of the conveyor belt and reduce maintenance requirements. Impact beds should provide maximum protection and durability, ensuring conveyor systems can handle the heavy and often abrasive materials common in mining operations without frequent belt replacements.

Accessories

Alongside core components, Luff offers a range of accessories that enhance performance and reliability:

- Belt brush cleaners remove residual material to prevent buildup and slippage.

- Lagging solutions increase belt traction and prolong pulley life.

- Urethane products, brackets, and take-up frames help maintain tension and alignment, further reducing the risk of failures or costly repairs.

Every accessory is engineered with durability and ease of maintenance in mind while keeping your operations productive and efficient.

Why Choose Luff

With over 45 years of experience in the industry, Luff Industries is a trusted manufacturer of premium conveyor components for mining and heavy industry. We specialize in what matters most: the critical parts that keep your conveyor operating at peak performance.

Our in-house engineering team uses advanced 3D modelling and FEA software to develop custom solutions, from modified idlers to engineered-class pulleys. Whether you’re building a new system or upgrading existing infrastructure, we design components to match your specific application, load conditions, and site challenges.

Heavy Industry Conveyor Systems by Luff Industries

Luff Industries’ commitment to quality, innovation, and customer service makes it a trusted partner for mining operations looking to optimize their material handling processes with superior conveyor components.

The mining industry requires conveyor systems of a certain calibre, and Luff Industries offers customized conveyor systems designed to meet the needs of your operation. With a focus on durability and versatility, our systems support various applications, making them an indispensable part of modern mining operations. Our comprehensive range of systems and custom solutions streamlines your operations, enhances productivity, and is durable and reliable.

Luff Industries is your trusted partner, and whether you require a standard belt or custom solutions, we can help create the best conveyor system for your business.