In demanding material handling environments, return-side wear is one of the most common – and costly – challenges operators face. Excess carry back, material buildup, and abrasive fines accelerate wear on return components and dramatically shorten belt life, leading to frequent shutdowns, cleanup, and unplanned maintenance.

Luff Industries’ engineered Urethane Disc Return Rollers to solve this problem at its source – delivering cleaner operation, longer service intervals, and up to 5x the lifespan of your average rubber disc return rolls.

The Problem | When Carry Back That Eats Away at Performance

When material builds up along the return path, it creates a chain reaction:

- Increased abrasion on the belt surface

- Accelerated wear on return components

- Higher risk of misalignment and tracking issues

- More frequent maintenance and downtime

Your standard rubber disc return rolls can often struggle to shed any sticky or abrasive materials collected over time, allowing buildup to grow and potentially damage your system and components.

The Solution You’ve Been Waiting For | Urethane Disc Return Rollers Engineered for Longevity

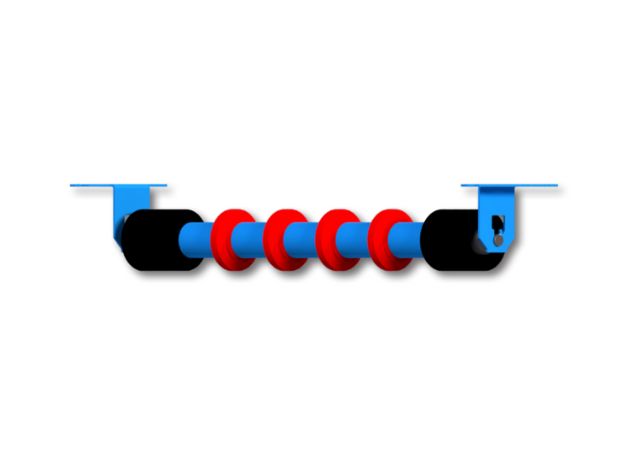

Luff Industries’ Urethane Disc Return Rollers are purpose-built to outperform traditional return rolls in high-wear applications. Their advanced design directly addresses carry back while protecting critical conveyor components.

Key Engineering Advantages

- Has a lifespan up to 5x longer than your standard rubber disc return rolls

- Self-cleaning disc design that gets rid of any debris before buildup occurs

- Polyurethane center discs engineered for extreme abrasion resistance or smoother function

- Dependable performance in temperatures up to 100°C

- Precision-fit options for belt widths from 18” to 96”

This targeted and strategic approach ensures that any high-wear zones are reinforced where they matter most – ultimately saving you time and preventing costly maintenance or repairs.

Self-Cleaning Performance | Protecting the Belt and Reducing Constant Maintenance

The self-cleaning action of Urethane Disc Return Rollers minimizes material accumulation on the return side. By preventing fine debris from building up or sticking, these rollers help:

- Reduce unnecessary abrasive contact with the belt, elongating your conveyors lifespan

- Lower the cleanup requirements beneath the conveyor – less mess is always a plus

- Help maintain consistent system performance

Cleaner operation means fewer interruptions – and longer component life for your conveyor system.

Built for Real-World Conditions | Tough Where Others Falter

In heavy-duty environments where components are under severe demand, you don’t want components that degrade under pressure – you want components that help your operation do MORE. Luff Industries Industries’ Urethane Disc Return Rollers are designed to thrive where standard options often fall short:

- Extreme abrasion

- High temperatures

- Non-stop operation

The polyurethane center discs within this component provide concentrated durability in the highest-impact zones, delivering consistent performance even in punishing conditions.

Precision Fit & Live Shaft Design | Reliability You Can Finally Count On

Available in standard belt widths from 18” to 96”, Urethane Disc Return Rollers integrate seamlessly into any of your existing conveyor setups.

Luff Industries’ live shaft design further enhances this reliability by ensuring consistent rotation, improved load handling, and reduced stress on the bearings – all contributing to longer service life and smoother operational impact overall.

The Real-World Value | Where Lower Costs Meet Higher ROI

By extending conveyor service life up to 5x, Urethane Disc Return Rollers help operations:

- Reduce replacement frequency – helping your operation run smoothly and on time.

- Minimize unplanned downtime – say goodbye to unnecessary delays.

- Lower labor and maintenance costs – ensuring a more cost effective approach.

- Protect belt investment over the long term – reducing replacement frequency.

Fewer shutdowns and longer-lasting components translate directly into measurable ROI.

The Bottom Line | Smarter Performance

When it comes to efficiency, durability and seamless function matters. These Urethane Disc Return Rollers offer a proven way to control carry back, protect other conveyor components and help them do their job, and keep operations running longer with fewer delays or frustrating repairs.

For operations focused on timeline efficiency, cost control, and long-term performance, upgrading to Urethane Disc Return Rollers isn’t just an improvement – it’s a strategic investment.

Contact us at Luff Industries to equip your operation with the Urethane Disc Return Rollers and increase your performance today!