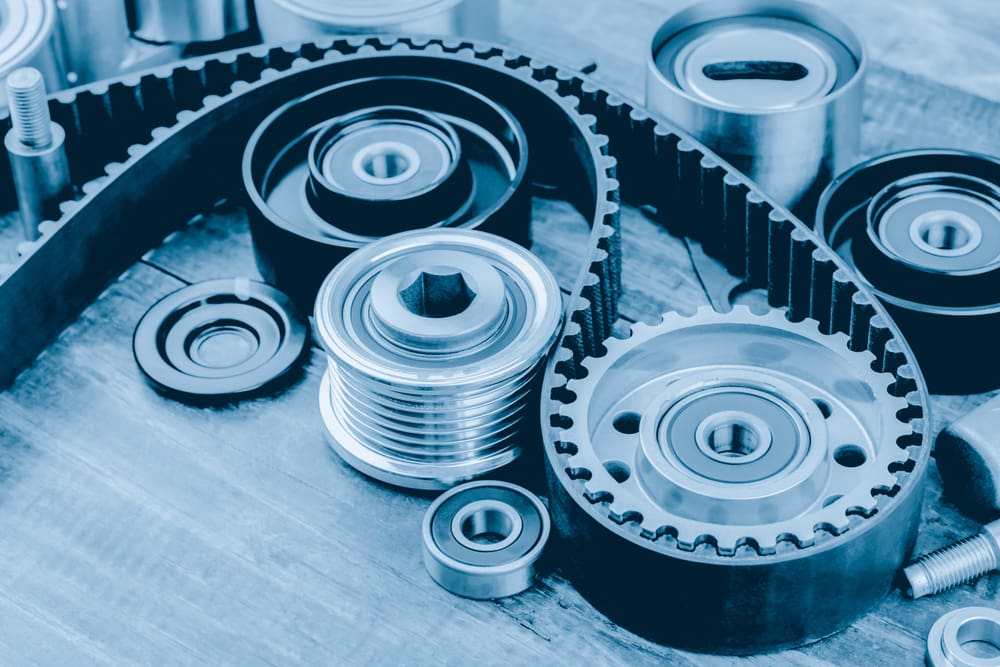

In industrial or heavy-duty environments, efficiency isn’t a luxury – it’s a requirement. When your site demands moving, lifting, and redirecting heavy loads of material safely and consistently this is where your equipment must work with physics, not against it. This is where Pulleys for industrial work save the day.

While pulleys may appear like a simple element at first glance, their longterm impact on overall productivity, safety, and operational flow is anything but basic. From reducing physical strain to improving workflow, to increasing control over heavy loads, industrial pulleys quietly power some of the world’s most demanding operations.

Here’s what you need to know about Pulleys…

What Makes Industrial Pulleys So Essential?

At the core of it all, pulleys are mechanical components designed to change the direction of a travelling force and manage different levels of load distribution. In industrial or heavy-duty applications, this translates to safer handling of heavy or awkward materials, smoother motion for transport, and greater control during lifting or repositioning.

Without Pulleys for industrial work, many industrial processes would require significantly more manpower, higher risk exposure, deeper investment pockets and longer completion times.

Pulleys simply allow work to be done smarter – not harder.

How Industrial Pulleys Provide a Mechanical Advantage

Mechanical advantage is where pulleys truly shine the brightest!

By redistributing load weight and altering the direction of force, pulleys reduce the amount of effort required to move heavy objects, sediments or material. When multiple pulleys are in use simultaneously the force needed can be reduced even further, allowing the system’s operators to handle the loads that would otherwise be impractical, complicated or unsafe.

In real-world industrial settings, this looks like:

- Less strain on project workers and equipment

- More precise control over any heavy loads

- Improved safety during lifting and movement requirements

- Increased efficiency across all operations

Pulleys for industrial work aren’t just about lifting – they’re about optimizing how and where force is applied to ensure smooth and optimal conveyor functionality.

Why Pulleys Are a Smart Investment for Industries

Industrial pulleys don’t just support operations – they improve them, tremendously.

Increase Productivity

By reducing manual effort and streamlining load movement, pulleys help teams complete tasks faster and with greater consistency.

Enhance Safety

Controlled load movement ad traction minimizes sudden shifts, weight drops, or overexertion on hte conveyor system – helping reduce workplace injuries and equipment damage.

Provide Long-Term Cost Efficiency

When you integrate durable, well-engineered pulleys into your conveyor system, it reduces overall downtime, maintenance demands, and replacement frequency – ultimately delivering strong ROI in the long-run for mining, agriculture and construction projects.

Common Types of Industrial Pulleys

Different applications demand different pulley options. Understanding the basics upfront helps ensure you and your team choose the right solution toi use for the job.

Fixed Pulleys

Mounted in a stationary position, fixed pulleys function by changing the direction of force without reducing overall load weight. They’re ideal when space is limited or operator positioning is a concern.

Movable Pulleys

Attached to the load itself, these movable pulleys reduce the amount of force required to lift by distributing weight more evenly and efficiently.

Combination Systems

By combining fixed and movable pulleys together for the same task, operators gain increased mechanical advantage, allowing heavier loads to be managed with greater ease and more reliable control.

Each configuration supports Pulleys for industrial work in different ways, depending on operational needs.

Choosing the Right Industrial Pulley

When selecting the correct pulley, it is just as important as using one at all. Moving forward with the wrong choice can lead to inefficiency, premature wear or damage, or even safety concerns.

Key factors to consider include:

- Load weight and frequency of use

- Operating environment (is it abrasive, wet, or high-impact conditions?)

- Required durability and lifespan

- Precision and alignment requirements

High-quality manufacturing, proper materials, and proven engineering ensure pulleys perform reliably under pressure – exactly what industrial operations demand.

Built for the Work That Keeps Industry Moving

From lifting heavy-duty materials to supporting smooth, controlled motion, Pulleys for industrial work are essential in many of our modern-day industries and reduce overall strain on conveyor systems, increase safety, and unlock workflow capabilities that will help operations grow and scale with confidence.

When designed and manufactured with precision, pulleys become more than components – they become performance multipliers that keep industrial work moving forward, day after day.

For more information on how to choose your perfect Pulley for the job, contact Luff Industries today!