Luff offers a complete line of conveyor components and accessories to keep your conveyor system running at optimal efficiency. Being an SKF Equipped Partner means Luff is supplying customers with the highest quality bearings on the market. Thorough testing of all Luff product and proven in the field, gives our customers the confidence to rely on Luff, even in the most demanding applications.

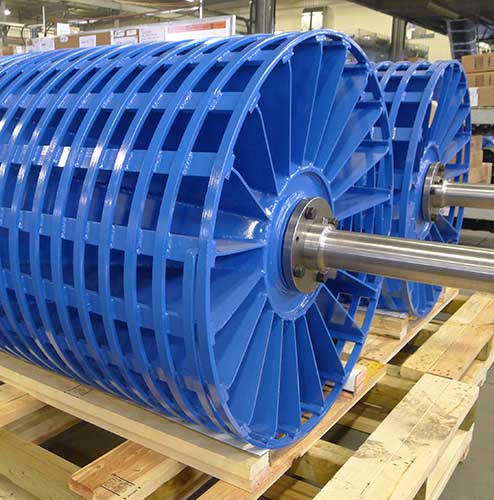

Luff Pulley’s are built to withstand the harshest of applications. Each element is designed and manufactured to create a pulley that is unmatched in quality and dependability. There are a variety of types available to suit your application needs.

Showing all 6 results

Luff Industries Ltd. warrants that the products it manufactures are free from defects in material and workmanship, when used under normal operating conditions. The duration of this warranty is 24 months from the date of delivery, or 2,000 hours of operation, whichever occurs first.

If a defect is found to arise from manufacturing, the customer must notify Luff Industries Ltd. in writing, within 30 days from the date of failure before proceeding with repairs or returning the product. Luff Industries Ltd. will correct any defect in materials or workmanship by repair or replacement of the defective product. Luff Industries Ltd. shall not be responsible, under any circumstances, for more than the cost of repair or replacement of the defective product. Non-compliance of the above conditions can void the warranty and Luff Industries Ltd. will not be responsible for the cost of repairing or replacing the product.