Luff offers a variety of pulley lagging including rubber, ceramic lagging, and weld-on lagging. ughtop, and Ceramic.

Rubber Lagging

50/60 durometer, shore A SBR rubber lagging is bonded directly to the pulley rim. Chevron, Herringbone and Diamond Groove are all available. Rubber lagging with a smooth finish can also be supplied. If grooving is required, direction of rotation is required. Rubber lagging prevents slippage by shedding moisture and adds a layer of protection against wear and debris build-up on the pulley face.

Richwood Redi-Lagg

Richwood Redi-Lagg is available in a full line of rubber weld-on lagging and ceramic weld-on lagging to cover most applications. Redi-Lagg-R has an aggressive tread pattern, providing a superior belt gripping power and longer service life. Redi-Lagg-C is made with the same industry leading technology used in Richwood Combi-Lagg ceramic lagging, providing 4 times longer wear than rubber lagging. Available in lengths up to 72” long and 1/2” and 3/4” thickness. Standard SBR and anti-static, oil resistant and fire retardant rubber blends are available.

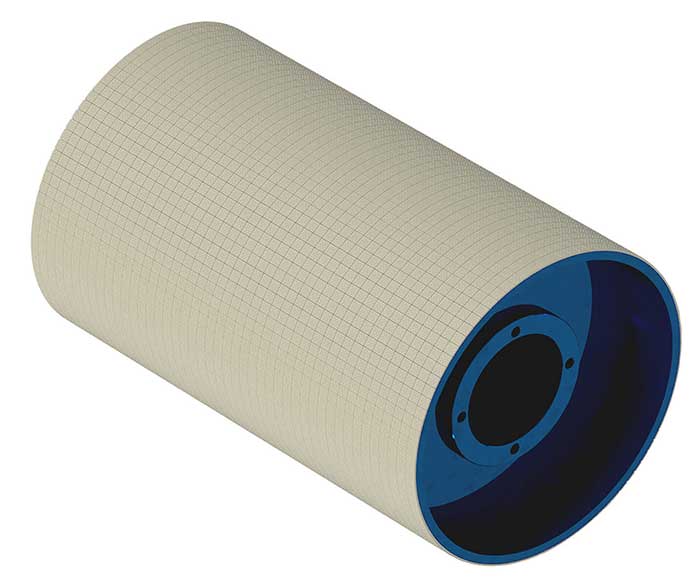

Ceramic Lagging

Richwood Combi-Lagg and Combi-Grip lagging uses Richwood R2000LS premium rubber compound and ceramic tiles with raised nubs to provide maximum grip, preventing belt slippage. Combi-Lagg & Combi-Grip provide higher friction values, improved belt tracking, and eliminates ice build-up in colder climates. There is less pulley wear, minimizing downtime and maintenance costs.

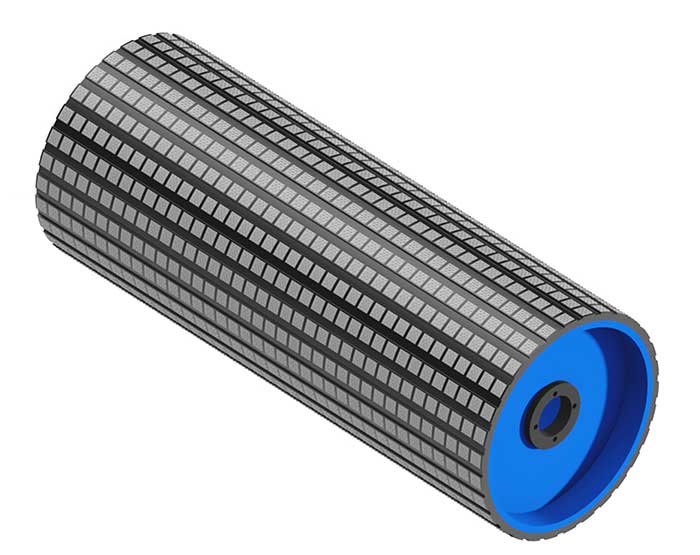

Direct Bond Ceramic Lagging

Ceramic tiles are bonded directly to the steel surface using the patented MultoLag high tensile flexible bonding system. The bonding system offers installed shear strength of >25 MPa. The tiles do not wear, reducing downtime and operating costs. Drive pulleys use high density ceramic tiles with studs to maintain maximum traction in all conditions. The studs have rounded edges to prevent belt wear and dewatering grooves help dissipate water and dirt, to maintain belt traction in wet or muddy conditions. Non-drive ceramic tiles are smooth, reducing friction and wear on both pulley shell and conveyor belt.

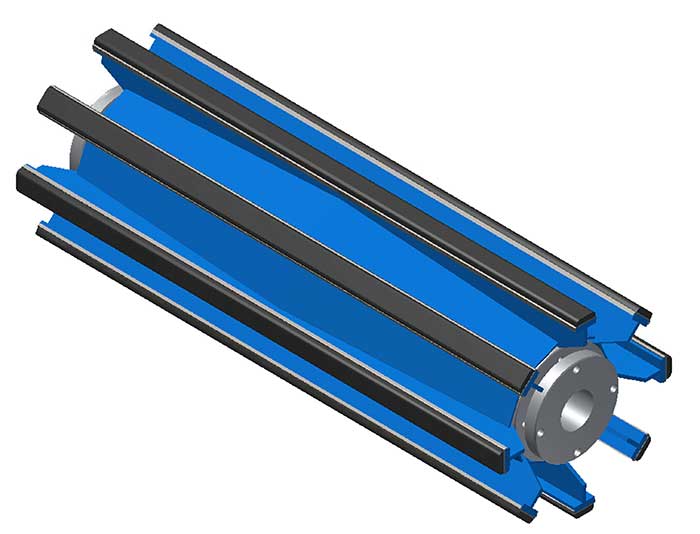

Wing Pulley Lagging

A blend of natural and SBR vulcanized to a 12-gauge steel channel. Engineered for maximum traction in both directions, allowing Luff Wing Lagging to be utilized on reversing belts.

- Reduce belt and pulley wear

- Can be used on reverse belt conveyors (two directions)

- Decrease downtime

- Reduce maintenance costs

- Prevent spillage

- Fits flat and crowned pulley

- Can be replaced without removing pulley