Businesses that rely on the performance of their conveyor components know how crucial it is to partner with a drum pulley supplier that is reliable. It could be the difference between minimal disruption to the business and unnecessary downtime that can cost companies a significant amount of revenue.

Whether you’re a new business looking for the right drum pulley manufacturer or you’re seeking to switch to a different supplier, here are some key factors to consider during your search.

What is the turnaround time for the drum pulley supplier?

When you’re dealing with drum pulleys or other conveyor parts that need repair or replacement, you need to know how quickly the turnaround time is. While drum pulley manufacturers can promise the lowest price or more incentives, if their turnaround time is too long, businesses may lose out on more money than they save on the low-cost product.

As a manufacturer of conveyor components, we provide delivery of just five days on non-stock standard products. This helps our clients reduce operational costs and minimize downtime by getting their business up and running as soon as possible.

What is the warranty offered by the drum pulley manufacturer?

Before purchasing a part, be sure to ask about the company’s warranty and policies related to the supplier’s workmanship. Typically, drum pulley suppliers offer a warranty on products that are used under normal operating conditions. Look for a supplier that offers at least 2 years warranty from the date of delivery that includes correcting defects in material or workmanship.

Be wary of any manufacturer that doesn’t have a warranty policy. Having a warranty in place demonstrates that the company is confident in the quality of its products and services.

How does the company differ from other drum pulley suppliers?

When you do a search on drum pulley suppliers, you’ll likely come across hundreds of manufacturers that offer the same products and services you’re looking for. To help you narrow down your search, we recommend reading reviews from past and current customers and take a look into how the company differentiates itself from other companies like them.

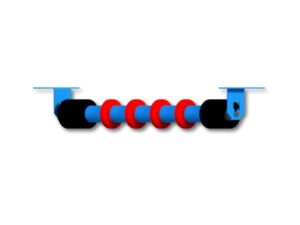

As a pioneer in the conveyor industry, what sets us apart from our competitors is our heavy duty pulleys. Luff uses steel tubing to manufacture all drum pulleys, instead of rolled steel, providing a thicker shell. This shell is then machined with a trapezoidal crown to ensure maximum pulley concentricity. The thicker shell absorbs more stress and protects against abrasive wear meaning less maintenance and reduced belt wear.

How can they help find a solution to your specific problem?

A good supplier carries the products that you’re looking for, provides good customer service, and quick turnaround time. A great supplier does all of the above while working with you to find the right solution for your specific application. When you have a unique conveyor system, you need a supplier that has an in-house engineering team that can design customized solutions. This ensures that you have the right part with the correct dimensions and material required.