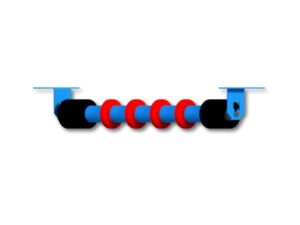

Your conveyor belt side guide rollers should work properly, if not, there will be problems throughout your entire system. All of your operations can be thrown off schedule. Drum and pulley manufactures are aware that this can lead to loss of both money and productivity.

Here are some common conveyor belt problems that can occur along the way.

- Conveyor Belt Mistracking

- Seized Rollers

- Material Spillage

- Blockages

- Belt Slipping

Conveyor belt rollers and idlers mistracking occurs when there’s a conveyor belt tracking problem…

Tracking is the process of managing and aligning the belt onto the right path, and it’s critical to ensure the graceful functioning and output of your system. Mistracking happens when something goes wrong along the track. In most cases, it means the belt has slipped to at least one side or another, and therefore the entire system has shifted out of alignment.

- Mistracking results in numerous negative consequences. it’s the potential to throw the whole system off its specified course. But the results also can be less extreme than this. Mistracking might simply cause uneven belt wear, which is the explanation for an entire host of other problems that could occur. If the belt slips entirely off the track, the entire system could begin malfunctioning. By catching this problem early, you’ll prevent it from worsening and creating a bigger issue.

-

When your belt starts tracking from side to side and experiencing frayed edges, be sure you perform conveyor belt alignment troubleshooting. Conveyor tracking issues could show up from many various parts of your system.

As soon as your belt starts mistracking, be sure to look for these potential problems:

1 – Debris and buildups are some of the first things you need to check for.

Buildups of debris, dirt, and residue could build over time around your belts, rollers and drum and wing pulleys. Be sure to inspect your entire system at all angles. Be sure to be thorough in removing any buildups you find.

2 – You need to make sure to clean your system regularly.

Your belts and rollers need to be kept clean. If you clean your system often, you can be proactive in preventing any issues that could arise as a consequence of leaving dirt, grime, and access materials to build up.

3 – You need to ensure your frame for your belt and rollers is level and square.

If your system is thrown out of alignment, or it is tilted at any angle but square, your conveyor will not run how it should. Normal usage or many factors that can affect your machine to be thrown out of alignment. Simply check that the sides are even or check it out with a level to ensure it is square.

4 – If the end pulleys are not even, this could lead to bigger issues.

While you are checking the frame and ensuring it is square, be sure you check the pulleys. If your pulleys are off, you could have parts take some serious wear and tear as well as your belts could start slipping.

5 – If your belt is not cut straight your whole system could be compromised.

When you are checking on all the above with your system, this is not something that you will check on each time. It is possible that you could attain a defective belt. If this happens, your belt mistracking could be wrecking your entire system. Be sure your belt is cut straight and perform an analysis on it when it is installed.

If you want to prevent all this from happening, Be sure you keep a good eye on your conveyor belts and rollers. By carefully watching your belts, you’ll catch many problems before they become larger issues that take time and money to repair.

No matter how careful you are, mistakes will still happen, and parts and equipment eventually break down. When this inevitably happens, it’s important to understand the way to reduce the chance of these damages from occurring.