Celebrate Canada Day with Luff Industries

As we gather to celebrate Canada Day, Luff Industries is proud to reflect on our journey as...

Read moreReducing Slip on Your Conveyor Belt and Increasing Productivity

When your conveyor belt slips in the middle of a job, it can result in material spillage,...

Read moreHeavy Duty Industrial Conveyor Systems for Mining Operations

Mining operations depend on heavy industry conveyor systems to improve efficiency, safety and productivity. Conveyor systems transport...

Read moreLuff Industries Will be at the Alberta Equipment Expo in Edmonton this April

We are excited to announce that we will be attending the highly anticipated Alberta Equipment Expo in...

Read moreLuff Industries Will be Attending the BCSSGA in Kelowna This April

We’re excited to share that Luff Industries will be attending the 2025 BCSSGA Conference, Trade Show &...

Read moreJoin Luff Industries at The AGG1 Show This March

We are excited to announce that we will attend the AGG1 Show in St. Louis this March....

Read moreJoin Luff Industries at SME MINEXCHANGE from February 23-26, 2025

Join Luff Industries in Denver, Colorado, at Booth 1729 at the SME MINEXCHANGE Conference and Expo and...

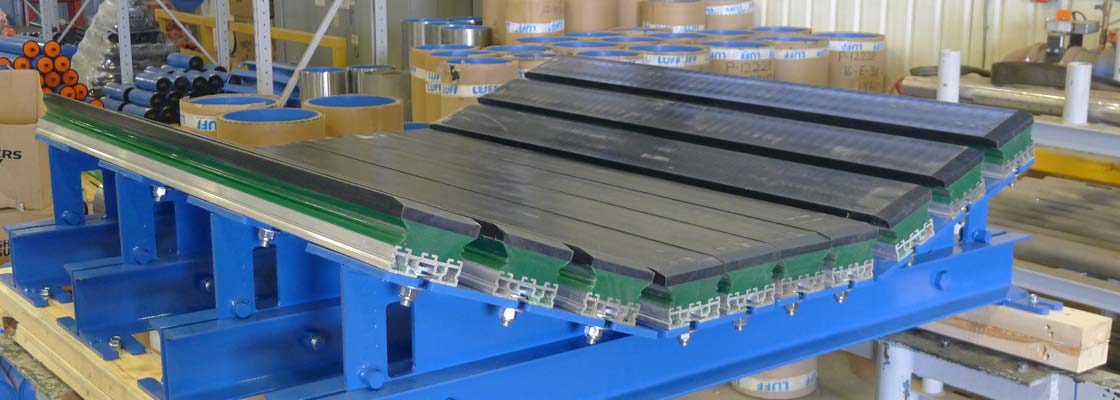

Read moreIndustrial Conveyor Impact Beds & Slider Beds: The Key to Conveyor Longevity

In heavy industries, maintaining the efficiency and longevity of your equipment is a necessity—especially for conveyor systems...

Read moreEverything You Need to Know About Industrial Conveyor Idlers

Conveyor systems are necessary in many industries, helping to move materials from one point to another efficiently....

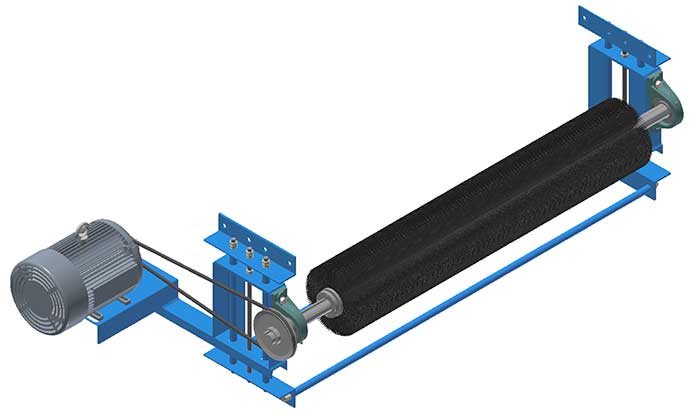

Read moreBenefits of Using a Belt Brush Cleaner for Your Industrial Conveyor System

In industrial environments, maintaining the efficiency and longevity of conveyor systems is crucial for smooth operations. The...

Read moreHappy Holidays From Luff Industries!

From all of us here at Luff Industries, we wish you and your loved ones a Happy...

Read moreHow to Select the Right Heavy Duty Conveyor Pulley Sizes

Industrial conveyor belt systems need to be optimized to perform the job they’re built to do. Selecting...

Read more