Drum Pulley manufacturers are a great place to turn to for advice on your conveyor systems and pulleys specifically. Many offer additional services including on-site inspections & surveys, assistance with design requirements and pulley refurbishment. Although maintenance can be done yourself, it is usually worth having a professional come in and assist with any issues that may arise to help prevent or minimize the potential damage to the pulley.

There are many reasons drum and wing pulleys fail. Here are some of the more common reasons. Having a properly functioning pulley can help reduce your risk of damaging other conveyor components including the belt and the idlers, reducing maintenance costs. It can also help increase your product output efficiency and decrease any down time associated with repairs.

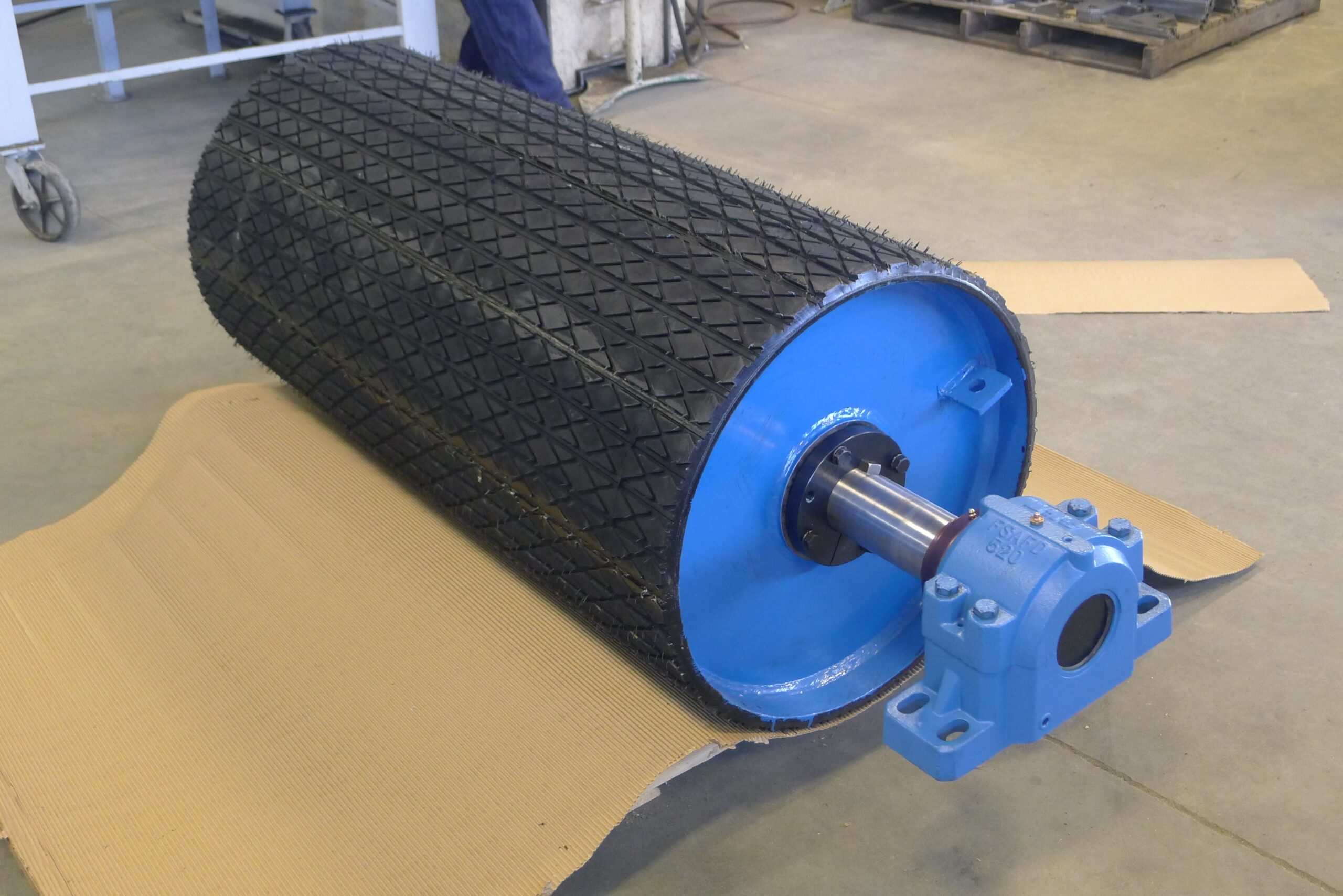

Let’s examine the 4 most common things that can cause damage to a pulley.

1 – Lack of Maintenance

- Pulley refurbishment is important. Although belts require very little maintenance, mishandling them is a common problem that can shorten the life of your belt and bring your system to a standstill. Problems with the belts are usually due to improper use of a belt or driven accessories such as a drum pedal or come from improper belt maintenance.

- Be sure your parts are inspected and maintained more often. This will save you money by ensuring your parts do not affect other parts so negatively… more parts affected will mean more downtime for repairs. This will lead to a significant drop in your production in lead time.

2- Does uneven weight distribution affect drum pulleys?

- If you have a lot of weight on a belt it can pull it to one side. This pulling over time can really cause issues when the parts that are responsible to keep your pulleys in balance are given overdue stress. Your drum pulleys are one of those that experience this overdue stress. Be sure that the weight is more even when products are being distributed onto your belt.

3- How do dust, dirt and grime affect your drum pulleys?

- Make sure you have a refurbishing schedule intact that you follow to ensure you keep your drum pulley parts cleaned, lubed, and inspected. In a factory, store, or outdoor environment, dust dirt and grime can build up over time in your drum pulleys. If you keep lubricating them while they are dirty, it can build up heavy grime. This can also corrode your parts. If you have heavy grime or corrosion, this can cause your drum pulleys to fail.

4- How can false track adjustment be hard on your pulleys?

- Something to be aware of is a false track adjustment. When the belt drifts off, also known as a false-track adjustment, it can cause problems with the pulley and prevent it from running well.

-

Issues can be caused by a worn pipe or roller, worn – worn or felted – rear drum bearings, an engine bearing, or something else related to drum movements.

-

If one of the rolls – the spoke – is damaged or broken, a hard pull on other integral parts can occur. If you hear a grinding tone… this is not good. If the grinding tone continues and the pulleys are difficult to turn, the pulley bearings may be damaged and/or worn and require replacement.

To determine whether the issue of your assembly is being caused by the drum bearings, you should inspect the drum bearing. To diagnose worn drums or bearings, remove the belt and try to turn on the drum by hand. If you see the same issue when it rotates by hand, a bearing may be the cause.

If you notice any of these symptoms, you can also check the pulley for other signs of damage, such as a hole in the pulleys or a broken drum bearing.